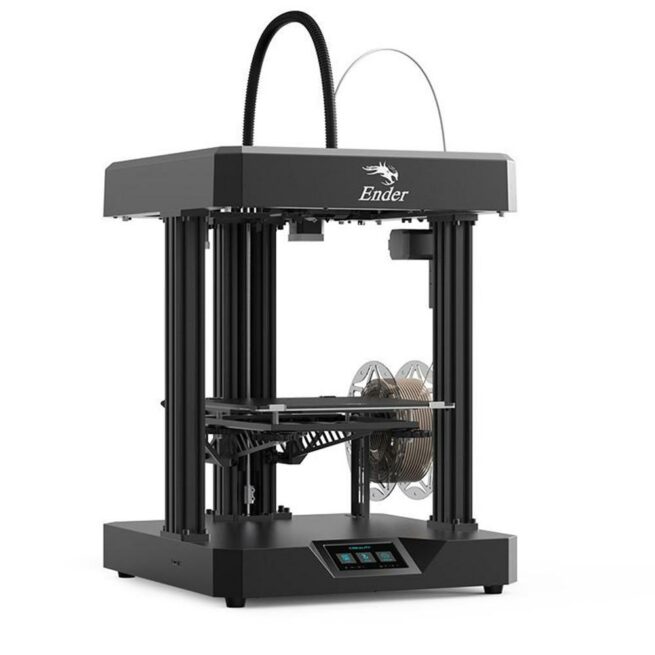

Creality Ender-7 FDM 3D Printer

Compared with the FDM counterparts, the Creality Ender-7 3d printer enjoys a high printing speed of 250 mm per second—when many of the homogeneous products carry the printing speed of 200 mm or 150mm per second, it remarkably outperforms them, setting up another new benchmark for the printing industry.

Ender-7 FDM 3D Printer Features

· 250 mm/s High-speed printing

· High precision linear rail

· Core-XY Structure

· A customized high volume nozzle

· Customized high-power motors

· High-speed cooling fans

· High-efficiency operational control algorithm

· Minimalist aesthetic design

Product Parameter

Molding technology: FDM

Printing size: 250 × 250 × 300 mm

Machine size: 430 × 460 × 570 mm

Package size: 570 × 540 × 400mm

Machine net weight: 17.2 kg

Package gross weight: 22 kg

Printing precision: ±0.1 mm

Nozzle diameter: 0.4 mm

Nozzle quantity: 1 piece

Resume printing function: Support

Filament detector: Support

Extrusion method: Remote extrusion

Hotbed temperature: ≤ 100℃

Nozzle temperature: ≤ 260℃

Printing layer thickness: 0.1mm-0.4mm

Print bed: Carborundum glass

Power rating: 350W

Printing material: PLA/ABS/PETG

Material diameter: 1.75 mm

Slicing software: Creality/Cura/Repetier-Host/Simplify3D

Power supply requirements: AC 100-120V /200-240V ,DC 24V

Supported languages: 9 languages (Chinese, English, Spanish, German, French, Russian, Portuguese, Italian, Turkish)

Operation mode: Online/Offline (USB Cable、TF Card)

High-speed printing, invigorating power

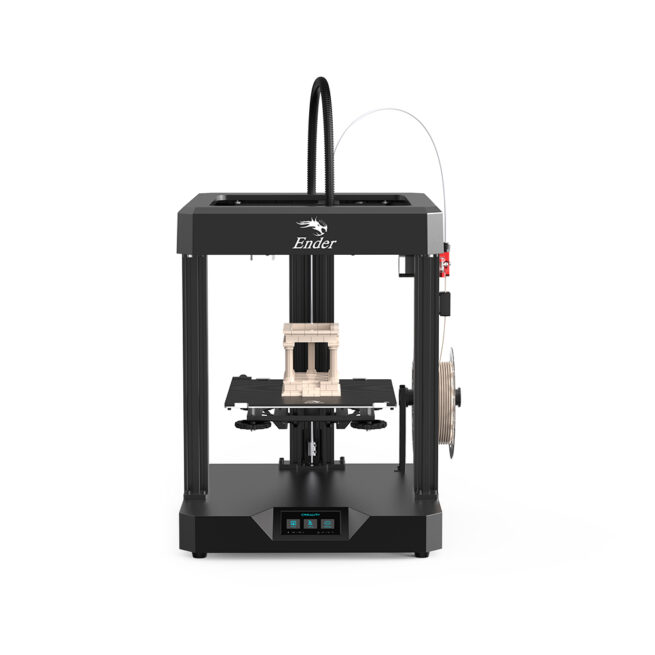

New breakthrough of speed, the normal printing speed of Ender-7 3d printer is up to 250mm/s, enjoy instant high-speed printing while maintaining the same molding precision quality.

Linear rail, higher precision

Utilizing linear rail technology to reduce movement resistance to a lower level, high precision positioning, and yet comes with high-speed stable movement.

Core-XY structure, precise control

Utilizing Core-XY structure, dual motors running parallelly with coordinated operations, faster speed, and higher precision

Smooth discharge and stable feeding

A customized high volume nozzle, the volume of the melting chamber has been increased to 50 mm³, and the volume of the heating block has been increased to 4000 mm³.

The filaments are fully melted and can be smoothly discharged when printing at a high speed.

Full-metal dual gear extruder, strong bite, greater extrusion force, uniform extrusion force, continuous and stable feeding.

Cooling sustainability despite under high temperature

The extruder’s cooling fan enables more stable feeding.

High-speed dual cooling fans are designed in butterfly-shaped wing ducts.

Compared to a single fan, dual fans increase overall air volume by 169%, ensuring fast cooling of high-speed print models

Reviews

There are no reviews yet.