Section 1: Introduction

3D printing is one of the greatest technological advances and innovations of the 21st century. Its value in the global market reached $190 million (USD) in 2021, and is expected to increase to $680 million (USD) by 2030. The factors that most influence this growth are the increase in environmental concerns regarding the waste generated by the sector, the possibility of customization and architectural flexibility using this technology, and the rapid creation of models and prototypes.

As the technology continues to develop, the possibilities for adoption and growth increase, and by 2028 its compound annual growth rate (CAGR) is expected to be of 91.5% compared to 2021.

What is 3D printing in construction?

3D construction printing (3DCP or 3DP) refers to the automated process of manufacturing construction elements or entire structures by means of a 3D printer.

However, instead of using ink like the traditional printers we’re used to, construction materials are printed layer-upon-layer, which is also why 3DCP goes by the name additive manufacturing or additive construction. It can be carried out both onsite and offsite.

Section 2: How does 3D printing work in construction?

The technology around 3D printing has been questioned many times since the 1980s. However, it has gained greater relevance thanks to the improvement of the technique itself that allows for the creation of a three-dimensional object by superimposing successive layers of material. This method of construction is very versatile and can help create specific components of a project and even various types of complex structures in its entirety such as houses or living spaces, offices, bridges, walls, modular structures, reinforcement molds, columns, urban furniture and even decorative elements.

Section 3: Benefits of 3D printing in construction industry

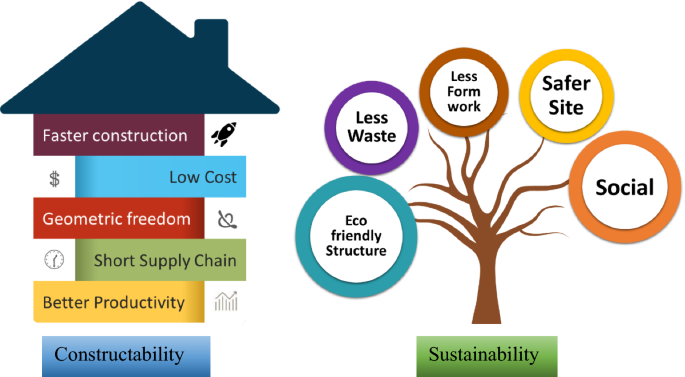

3D printing brings great benefits to the construction industry, being a solution that touches almost all areas of the value chain of the sector. From contributions to sustainability, increased productivity and support in challenges on the supply chain, this technology came to revolutionize the way we build.

Time reduction

With traditional construction methods, a project can take many months to complete, with the norm being that large projects take 20% longer than expected and adding up to 80% in cost overruns over the initial budget. However, 3D printing allows to reduce up to 70% of the time and a project can be completed in just hours or days, depending on its magnitude. Therefore, contractors can work on more projects and, consequently, increase their source of income.

More cost-effective and sustainable

3D printing allows the precise amount of material to be used to lift a structure, allowing up to 60% less waste to be generated at the jobsite. Likewise, there will be no surplus in the purchase of materials, assuming a reduction in costs both in its purchase and subsequent storage.

By reducing time and costs, companies will see an exponential increase in the benefits of this technology, which is also of great help in locations where there is a need for projects and a shortage of labor. By automating the creation of a structure through 3D printers, companies can see a reduction in labor costs of up to 80%.

Section 4: Opportunities and challenges for 3D printing in construction

Although the benefits of 3D printing in construction will continue to develop as more companies bet on this technology, achieving greater adoption of this method in the market is still a challenge.

We highlight the following points that intervene when making this technology even more trendier among industry professionals and why large companies are still dubious about it:

- Although 3D printing itself is more cost-effective when building, the necessary machinery continues to be very expensive both to acquire and to operate it, and large companies still do not bet on them in a significant way.

- The industry needs to develop more trained professionals to be able to handle the technology behind 3D printing, trained to design computer models, operate the equipment and provide proper maintenance.

- More regulations and legislation are needed for 3D printing in construction that allows for clear guidelines on its use and benefits of its implementation in new construction sites.

Section 5: Conclusion

3D printing is revolutionizing the construction industry in ways that were once unimaginable. From enhancing design flexibility and reducing construction time to minimizing waste and optimizing material usage, this technology holds tremendous promise for the future of architecture and infrastructure development. As we continue to innovate and refine these techniques, the potential for 3D printing to create sustainable, cost-effective, and aesthetically stunning buildings is truly exciting. Embracing this transformative technology is not just about improving efficiency, but also about redefining what is possible in construction, pushing boundaries, and shaping a more resilient built environment for generations to come.