How 3D Printers Work: From Idea to Object

Introduction

Industry 4.0 and 3D scanning are two well-known ideas that are at the forefront of innovation in a world where technology is developing at an astounding rate. These innovative technologies has the capacity to completely transform our interactions with both the digital and physical worlds, bringing about unthinkable changes to industries and procedures.

Fundamentally, 3D scanning is a revolutionary technology that enables us to connect the digital and physical realms. It accurately and meticulously captures the complex geometry of objects, transforming them into vibrant, digital representations. These digital twins provide a way to innovate in a variety of fields, including engineering, healthcare, the arts, and entertainment, in addition to helping to preserve our physical environment.

A new era of smart production and data-driven decision-making is simultaneously ushered in by the emergence of Industry 4.0, also known as the Fourth Industrial Revolution. The Internet of Things (IoT), big data, automation, and artificial intelligence are all included in this wave of technological integration. Industry 4.0 is revolutionizing the manufacturing process, optimizing urban areas, and managing supply chains—all while advancing efficiency and sustainability.

We will discover the technology and uses that make 3D scanning an invaluable tool as we go through the complex world of 3D scanning. We will examine these breakthroughs’ obstacles and constraints as well as the encouraging patterns that suggest 3D scanning and Industry 4.0 will play important roles in the future. We shall be better able to comprehend these technologies’ transformational potential and the ethical issues that support them thanks to this investigation. Welcome to the realm of Industry 4.0 and 3D scanning, where the possibilities are endless and present fresh opportunities for advancement.

Section 1: Understanding 3D Scanning

Definition and Historical Evolution of 3D Scanning:

The process of capturing the geometry of the physical world and converting it into digital 3D models is known as 3D scanning. Although this technology is now widely available, it has a long history of evolution.

3D scanning dates back to the mid-twentieth century, when industrial manufacturers sought more precise and efficient methods of replicating physical objects and structures. Despite their limitations, early 3D scanning methods found specialized applications in industries such as aerospace and automotive manufacturing.

3D scanning has become more accessible thanks to developments in software, sensors, and processing power. These days, smaller companies and individuals can also access it instead of just large industrial conglomerates. This historical development shows how 3D scanning evolved from a specialized industrial tool to a widely used, adaptable technology with applications in many different industries.

Principles of 3D Scanning Technologies:

Regardless of the precise technique employed, the fundamentals of 3D scanning technologies remain the same. These principles cover energy emission, interacting with the object, and identifying and evaluating the information that is returned.

Emission: The process of 3D scanning entails the emission of energy in the direction of the object being scanned, such as laser beams or structured light. The surface of the object is in contact with this released energy.

Interaction: The surface of the object and the released energy interact. Depending on the technology, this interaction takes on different forms. For example, structured light scanners project patterns onto the surface, while laser scanners bounce laser beams off the object.

Detection and Analysis: The scanner’s sensors identify the energy that is returning and quantify its intensity, colour, and distance. After processing, a 3D model of the object is produced.

Types of 3D Scanning Methods: Two broad categories exist for 3D scanning techniques: contact and non-contact.

Contact Methods: In these techniques, the object is physically touched. For example, Coordinate Measuring Machines (CMMs) take measurements by touching the object’s surface with a probe. Even though they are extremely accurate, they work poorly with delicate or complex objects.

No-Contact Techniques: These days, non-contact 3D scanning technologies are more widely used because of their speed and versatility. They consist of:

Laser Scanning: This method collects accurate point cloud data by using laser beams.

Structured Light Scanning: To generate a 3D model, patterns are projected onto an object’s surface, and deformation is measured.

Photogrammetry: This method builds a three-dimensional model by taking pictures from various angles and triangulating them.

LiDAR: To create 3D maps, laser pulses are emitted and their return time is measured.

CT Scanning: This method builds cross-sectional images from X-rays that can be combined to form a three-dimensional model.

The selection of technology is contingent upon particular application requirements, with methods differing in terms of accuracy, speed, and applicability.

Resolution, Accuracy, and Precision in 3D Scanning

Accuracy, precision, and resolution are crucial components of 3D scanning. The resulting 3D model’s dependability and quality are determined by these parameters.

Accuracy: This gauges how well the scanned model mimics the actual item. In industries where accuracy is critical, like aerospace engineering or healthcare, high-accuracy scanners are essential.

Precision: Measures the degree of consistency between subsequent measurements. When scanning the same object more than once, high-precision scanners yield results that are almost identical, which is essential for applications like manufacturing quality control.

Resolution: The density of the point cloud determines the resolution, which is a measure of the 3D model’s level of detail. Finer details are captured by higher resolution scanners, which is crucial in disciplines like archaeology.

Section 2: 3D Scanning Technologies

Now that we have a better understanding of the world of 3D scanning, let’s explore the technologies that power this revolutionary process. These technologies are the ones that power the creation of intricate 3D models from real-world objects. The following is a brief synopsis of the main 3D scanning technologies:

Laser Measurement

One popular 3D scanning method is laser scanning. It measures the return of laser beams emitted onto an object’s surface. Although it may have trouble with transparent or reflective surfaces, this method is highly valued for its speed and accuracy, which makes it indispensable in industries like engineering and architecture.

Structured Light Scanning

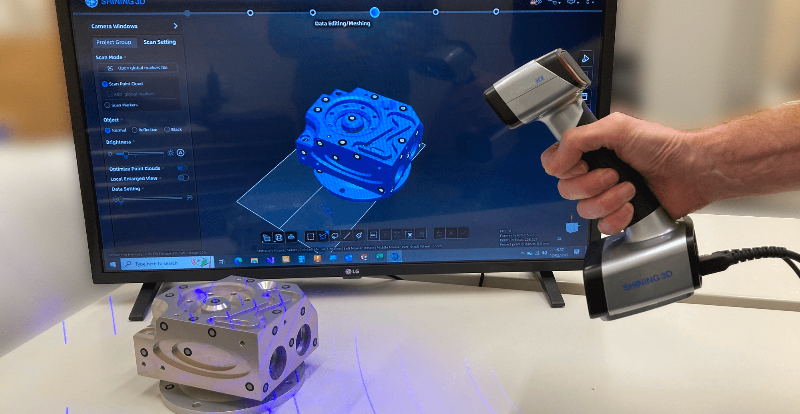

Using structured light scanning, a 3D model is produced by projecting a pattern of light onto an object’s surface and analysing the pattern’s deformation. Because of its exceptional ability to capture fine details and textures, this technology is perfect for digitizing historically or culturally significant objects, as in the case of art restoration projects.

Photogrammetry

In order to create a three-dimensional model of an object, photogrammetry requires taking several pictures of it from various perspectives. The results of this flexible, non-contact method, which depends on lighting and image quality, can be used in topography, gaming, and surveying.

Light Detection and Ranging, or LiDAR

LiDAR technology generates extremely precise 3D maps by pulsing lasers and timing their return. LiDAR primarily finds use in forestry, autonomous vehicles, and environmental surveying, excelling in large-scale outdoor mapping.

CT Scanning

Computed tomography (CT) scanning, which is frequently related to the medical field, uses X-rays to produce cross-sectional pictures of objects that can be combined to form three-dimensional (3D) models. It is essential to medical diagnosis and treatment planning, and its uses range from examining an object’s internal structure in various industries.

Every 3D scanning technology has advantages and disadvantages that are particular to the demands of a given task. For example, structured light scanning is ideal for maintaining the details of cultural artifacts, while laser scanning is preferred in engineering applications. For extensive outdoor mapping, LiDAR is the method of choice, but photogrammetry is more versatile.

The upcoming sections will delve into practical instances of how these 3D scanning technologies are transforming a range of industries, demonstrating their multifarious uses.

Section 3: Applications of 3D Scanning

When we look at how 3D scanning is being used in various industries, we can see its full potential. Now let’s explore several important domains where 3D scanning can have a revolutionary effect:

Manufacturing and Engineering

3D scanning is a vital tool in production and engineering. It makes prototyping, reverse engineering, and quality control easier. Manufacturers ensure that parts and products fulfil the required criteria by using 3D scanning to gather exact data of real objects. For instance, 3D scanning helps in the automotive industry to develop and validate vehicle components, which speeds up the production process.

Applications in Healthcare and Medicine

3D scanning is crucial to the healthcare industry for patient care, medical imaging, and the creation of personalized implants and prostheses. To assist in diagnosis and surgery planning, medical practitioners employ CT and MRI scans to construct 3D models of the human body. To create extremely exact digital impressions for dental procedures, dentists use 3D scanning.

Architecture and Construction

3D scanning is used by builders and architects for as-built modelling, building documentation, and site study. Errors in construction projects are decreased by using scanning equipment to survey and document existing structures. When renovating historical buildings, technology is very helpful because it makes sure that any new work precisely matches the original plan.

Preservation of Cultural Heritage

It has been shown that 3D scanning can save cultural heritage preservation. It makes it possible to carefully digitize sculptures, historical locations, and relics. Cultural organizations have the ability to digitize their holdings and make them publicly accessible. Additionally, by offering comprehensive 3D models for reference, this technology helps with restoration efforts.

Gaming and Entertainment

3D scanning is used in the entertainment sector to create lifelike computer-generated imagery (CGI) and design characters and sets. 3D scanning is used in video games to create lifelike characters and settings that draw gamers into engrossing virtual worlds. 3D scanning is also used in motion capture to record actor motions for animation.

The Automobile and Aerospace Industries

In the aerospace sector, 3D scanning is essential for quality control and safety inspection of aircraft parts. It is employed in the analysis of wear and tear effects and dimensional inspections. To improve vehicle performance and safety, the automobile industry uses 3D scanning for vehicle design, aerodynamics testing, and crash simulation.

Design and Art

Designers and artists use 3D scanning for their creative work. It helps in the creation of jewelry, elaborate sculptures, and personalized furniture. Additionally, 3D scanning opens up new creative possibilities for artists by allowing them to edit and merge real-world things into digital art.

Three-dimensional scanning has a wide range of constantly growing uses. Technology is expected to have an increasing impact on creative sectors and fields as it develops, creating new opportunities and pathways for creativity.

Section 4: Challenges and Limitations

As strong and adaptable as 3D scanning is, there are drawbacks and restrictions with this technology. It’s essential to comprehend these factors in order to make wise choices while using 3D scanning in practice:

Complex Geometries and Reflective Surfaces

Incorporating intricate geometries or reflecting surfaces may provide challenges for 3D scanning. Because line-of-sight measurement is a prerequisite for standard 3D scanning techniques, these difficulties occur. Complicated forms or highly reflecting materials might make it difficult for the scanners to collect reliable data, which can lead to skewed or incomplete 3D representations.

Data Organization and Processing

The amount of data produced by 3D scanning might be rather large. Handling, analysing, and keeping this data can be very difficult. Sophisticated software and robust hardware are needed to effectively manage the enormous point cloud collections. Furthermore, the time and computational power needed for data processing might be a barrier, especially for applications that need to process data quickly.

Environmental Aspects

The surroundings can have an impact on 3D scanning. The quality of scans can be affected by variables like humidity, temperature, and ambient lighting. For instance, laser-based scanner accuracy may be impacted by interference from intense interior lighting or direct sunshine. Changing weather can make scans difficult in outdoor situations, especially for environmental mapping applications.

Privacy and Ethical Issues to Consider

There are privacy and ethical issues with the usage of 3D scanning, particularly in public areas. When 3D scanning technology is used for data collecting or monitoring, privacy and data security concerns become critical. Finding a balance between personal privacy and the advantages of 3D scanning is a complicated matter that needs careful thought and regulation.

The Price and Availability

Although the cost of 3D scanning technology has decreased, sophisticated, high-precision scanners can still be quite costly. For individuals and small businesses wishing to use 3D scanning, this expense may be a deterrent. Moreover, accessibility for individuals lacking specialist knowledge may be restricted due to the proficiency needed for efficient 3D scanning and data processing.

Resolving these obstacles and constraints is a continuous process. Technological developments like better algorithms and more approachable software are meant to break through these obstacles. Furthermore, laws and moral standards are being created to guarantee the appropriate application of 3D scanning technology.

Comprehending these obstacles and constraints is crucial to fully utilizing 3D scanning while minimizing the related hazards and guaranteeing its conscientious implementation in diverse sectors and situations.

Section 5: The Future of 3D Scanning

Significant developments and breakthroughs in 3D scanning are anticipated in the future, expanding the capabilities of the technology to new heights:

Oncoming Patterns

The integration of 3D scanning capabilities with other state-of-the-art technologies is now underway. The combination of augmented reality, 3D printing, and 3D scanning has the potential to completely transform how people interact with the real and virtual worlds. This convergence will assist businesses ranging from product design to healthcare by enabling real-time customization and prompt prototyping.

Enhanced Mobility

Conventional 3D scanners have been big and stationary. Handheld and portable 3D scanners are, nevertheless, becoming more widely available. Particularly in industries requiring fieldwork, like construction and archaeology, and in applications where mobility is critical, like cultural asset protection, these lightweight, mobile devices offer flexibility and ease of use.

Reduced Expenses

It is anticipated that the cost of 3D scanning technology would decrease due to economies of scale and ongoing improvements in hardware and software. By lowering the cost, high-precision 3D scanning will become more affordable for consumers and small enterprises, broadening its potential uses and advancing the democratization of technology.

Increased Rapidity and Effectiveness

3D scanning is becoming faster and faster all the time. More rapid scanning procedures are under development, allowing for faster data collection without sacrificing accuracy. Applications where quick decisions are essential, such as quality control in manufacturing, will profit from this increased efficiency.

Smart Cities and Industry 4.0

Within the framework of Industry 4.0 and smart cities, 3D scanning will become ever more important. It will help build digital twins of urban and industrial processes, enabling predictive maintenance, real-time monitoring, and efficient resource allocation. This will improve sustainability and efficiency in a number of sectors.

3D scanning is going to have a very bright future. This revolutionary technology will find new uses in Industry 4.0 and smart cities, as well as in areas like as cost reduction, enhanced speed and efficiency, greater portability, and integration with other technologies. It looks like 3D scanning will keep changing industries, streamlining processes, and deepening our comprehension of the real world.

Section 6: Tips for Getting Started with 3D Scanning

Here are some useful pointers to get people and companies interested in using 3D scanning into their operations started:

State Your Objectives: Start by determining your unique requirements and goals for 3D scanning. Knowing your goals clearly is crucial, whether they are for product design, quality assurance, cultural preservation, or any other reason.

Select the Appropriate Scanner: Choosing the right 3D scanner is essential. Think about things like the kind of objects you plan to scan, the amount of accuracy needed, and your financial constraints. There are several kinds of 3D scanners, each with unique advantages, such as desktop, handheld, and industrial-grade models.

Get to Know the Basics: Become acquainted with the underlying ideas of 3D scanning. Making sense of ideas like as mesh models, point clouds, and software tools will enable you to explain your needs clearly and make well-informed decisions.

Software Selection: Just as crucial as the scanner itself is the software you use to handle and modify the data from 3D scans. Examine various software solutions while taking your skill level and the functionality you need into account.

Education and Training: Make educational and training investments. Numerous organizations provide workshops and courses on 3D scanning software and procedures. These tools can help you become more proficient and quicken your learning curve.

Experiment and Practice: +As with any ability, 3D scanning gets better with use. Try out various scanning methods and objects to hone your skills and acquire experience.

Data Management: Create a plan for handling data. For effective utilization, 3D scan data must be stored and organized. Put in place a strategy that makes sure your priceless scans are easily accessed and backed up.

Work Together and Network: Interact with the community of 3D scanners. Participate in industry events, attend online forums, and build relationships with experts who may offer guidance and insights.

Keep Post-Processing in Mind: Recognize that post-processing could be required to improve the quality of your scans. With post-processing tools, you may improve, align, and tidy up your 3D models.

Start Small: Before taking on more complicated tasks, it’s advisable to begin with simpler ones if you’re new to 3D scanning. This enables you to gradually improve your talents.