How 3D Printers Work: From Idea to Object

Section 1: Introduction

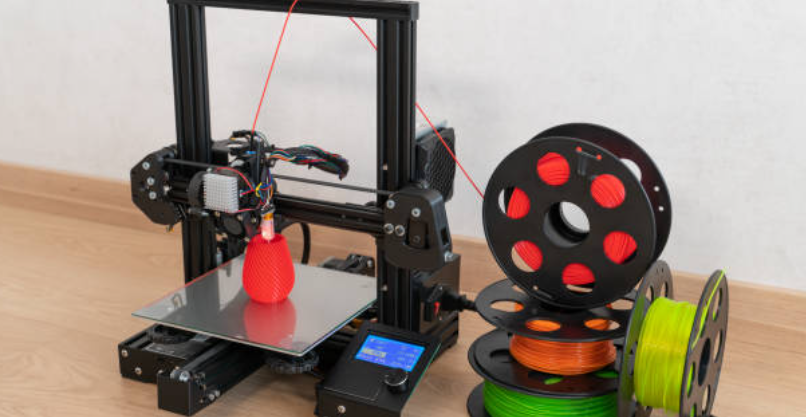

The process of bringing ideas to life has been transformed by 3D printing, which converts computer concepts into physical items. A vital component at the center of this technology is the filament. Selecting the appropriate filament is an essential choice that can have a big influence on how well your 3D printing items turn out. Your doorway to comprehending the world of 3D printing filaments and making wise decisions is this thorough guide.

Layer by layer, the magic of 3D printing is created, and the material that is deposited, melted, and sculpted into those layers is the filament that you utilize. However, not all filaments are made equally, and there might be significant variations amongst them. The wide universe of 3D printing filaments, from the everyday to the unusual, will be made understandable with this guide.

Section 2: Common Filament Types

Several popular filament kinds, each with an own set of qualities and uses, are prevalent in the field of 3D printing.

Polylactic acid, or PLA, is the poster child of filaments used in 3D printing. Its bright color selections, biodegradability, and simplicity of usage are well known. PLA is perfect for novices and has many uses, ranging from prototypes to ornamental objects.

Acrylonitrile Butadiene Styrene, or ABS, is a strong and long-lasting material that is ideal for functional parts. Although it needs a heated print bed, it can tolerate greater temperatures. ABS is frequently utilized in industrial and automotive contexts.

PETG, or polyethylene terephthalate glycol, is a material that combines the advantages of ABS and PLA. Similar to PLA, it is simple to print, but ABS offers greater strength and durability. When creating prototypes and mechanical pieces, this filament is highly recommended.

Thermoplastic polyurethane, or TPU, is a flexible filament that is ideal for use in prostheses, shoe bottoms, and phone cases because it can stretch and bend. Its rubber-like properties allow for a multitude of imaginative possibilities.

Nylon: Due to its resilience to deterioration and long lifespan, nylon is highly valued. It is frequently utilized for functional elements needing great strength, such as gears and bearings.

Polyvinyl alcohol, or PVA, is a water-soluble support substance that is utilized in 3D printing with dual extrusion. It dissolves in water without harming complicated, sophisticated structures.

We’ll go into more detail about each type of filament in the next sections, examining its special qualities and uses. Knowing these choices will enable you to select the ideal filament for your unique 3D printing requirements.

Section 3: Specialty Filaments

Although a wide range of 3D printing needs are met by conventional filaments like PLA, ABS, PETG, TPU, Nylon, and PVA, the field of 3D printing is always changing, leading to the development of specialty filaments with distinctive qualities. With these specialized filaments, 3D printing creations can be innovative and creative. Let’s investigate a few of the more fascinating choices:

Wood-Infused Filaments: These filaments give 3D prints a texture and appearance similar to wood. They are often a blend of PLA and wood particles. They work great for making sculptures, decorations, or anything that looks better with a rustic, natural aesthetic.

2. Metal-Infused Filaments: These filaments combine fine metal powders, such as copper, bronze, or stainless steel, with PLA. This produces 3D printouts that have the appearance of real metal objects, which makes them suitable for sculptures, jewellery, and other artistic creations.

Carbon Fiber Filaments: These add strength and rigidity to 3D printed objects. They are employed in products like drones, RC car components, and engineering prototypes where structural integrity is essential.

shine-in-the-Dark Filaments: These filaments, as their name implies, are phosphorescent, which means that when they come into contact with light, your 3D printouts will shine in the dark. These might be fun to use for making novelty objects or bright markers for dimly lit areas.

5. Colour-Changing Filaments: These filaments react to temperature changes by changing colour. Your 3D printed object changes colour as it warms up or cools down. For creative, whimsical, or temperature-sensitive applications, they’re fantastic.

Flexible Filaments: Specialized flexible filaments with different levels of flexibility exist in addition to TPU. They’re ideal for creating wearables, phone cases, and personalized gaskets.

Conductive Filaments: Suitable for embedded electronics and circuit projects, conductive filaments are made of materials that permit electrical conductivity.

Your 3D printing endeavours will benefit from the added creativity and utility provided by these specialist filaments. Gaining an understanding of their characteristics and their uses can lead to innovative opportunities for your projects. We’ll go into more detail about the choosing process in the parts that follow, making sure you pick the ideal filament for your particular 3D printing requirements.

Section 4: Choosing the Right Filament

Choosing the right filament for your 3D printer is essential since it affects the outcome and caliber of your prints. Consider the following while selecting the ideal filament for your project:

Project specifications: Establish the goal of your 3D print before anything else. Is it an artistic creation, a prototype, or a utilitarian component? The first step in choosing the appropriate filament is to comprehend the project’s needs.

Sturdiness and Strength: Take into account the physical characteristics your 3D print needs. Filaments such as ABS, PETG, or polymers impregnated with carbon fiber can be appropriate if strength and durability are crucial.

Flexibility: TPU and other flexible filaments are excellent options for applications that call for flexibility or impact resistance.

4. Temperature Resistance: Filaments with strong temperature resistance, like ABS, can be required if your 3D print will be subjected to high temperatures, such as automobile parts or electronic enclosures.

Layer Adhesion: Parts with intricate geometries or significant mechanical stress might benefit from the superior layer adhesion that some filaments, such as nylon, offer.

Print Difficulty: Take into account your degree of 3D printing expertise. While some filaments, like PLA, are easier for beginners to print with, others can need more experienced users and sophisticated print settings.

Material Compatibility: Verify that your 3D printer and the filament you select are compatible. Verify the printer model’s specifications and the advice provided by the manufacturer.

8. Cost: The pricing points of various strands vary. Take into account the filament’s price and how much it will cost for your project.

Aesthetics: Take into account the filament’s pleasing appearance. You may give priority to filament colour, texture, or unique qualities like wood-infused or glow-in-the-dark materials for artistic or decorative creations.

Environmental Considerations: While other materials might not be as environmentally concerned, PLA is known for being biodegradable, making it an eco-friendly option.

You may select the ideal filament for your 3D printing project by carefully weighing these considerations and comparing them to the features of different filaments. Practical advice for producing effective 3D prints with the filament of your choice will be covered in detail in the following section.

Section 5: Tips for 3D Printing Success

After choosing the best filament for your project, let’s look at some crucial advice to make sure your 3D prints turn out well. You can use your selected filament to get the best results by following these guidelines:

Calibration is Crucial: Adjust your 3D printer’s settings before beginning any prints. This include adjusting the nozzle temperature, levelling the print bed, and making sure the filament flow rate is correct. A successful print depends on accurate calibration.

Adhesion Technique: Select the appropriate adhesion technique for your filament. Depending on the type of filament, this could entail utilizing a heated bed, hairspray, or glue sticks.

Print Speed and Layer Height: To maximize print speed and layer height, modify your print parameters. Your 3D printing’ quality can be greatly improved by adjusting these settings.

Temperature Control: Make sure the print bed and nozzle temperatures are appropriate for the filament you’re using. For optimal outcomes, consult the manufacturer’s instructions. The optimal temperature ranges for different filaments vary.

Cooling: While little cooling is ideal for ABS, active cooling is beneficial for PLA and other filaments. Adapt the cooling fan settings to the situation.

Supports and Rafts: To avoid print failure, you might need to utilize supports or rafts, depending on how intricate your design is. These can be automatically generated by most slicing applications.

Print Orientation: Try out several print orientations to see which reduces overhangs and improves print quality.

Layer Adhesion: Extrusion settings should be optimized to provide strong layer adhesion. Preventing under- or over-extrusion problems is essential.

Filament Quality: Make an investment in premium filament from reliable suppliers. Poor-quality filament might clog the nozzle of your 3D printer and cause poor print quality.

Keep an eye on the print: Pay close attention to the print work, particularly in the initial layers. This enables you to identify any problems early and stop expensive malfunctions.

Post-Processing: If your print is finished, think about doing post-processing actions like painting, sanding, or, for larger projects, assembling several sections.

Learn from Mistakes: Failed printing shouldn’t deter you. Consider them as chances to strengthen your 3D printing knowledge and abilities instead.

You should have no trouble creating excellent prints with your selected filament if you adhere to these suggestions and keep improving your 3D printing methods. We’ll talk about safety precautions and how to store filaments properly in the next part to preserve the integrity of your materials.

Section 6: Safety and Storage

Ensuring safety in 3D printing is essential for a smooth and secure experience. Here are important safety considerations and best practices to follow:

Ventilation: Many 3D printing filaments release fumes, especially when printed at high temperatures. Ensure your 3D printer is in a well-ventilated area or consider using a dedicated enclosure with proper ventilation or a fume extractor. This is particularly important when working with filaments like ABS or PETG.

Printer Placement: Place your 3D printer on a stable and fire-resistant surface. Avoid leaving it unattended during long prints, and have a fire extinguisher nearby, just in case.

Filament Storage: Keep your filaments in a dry and airtight storage container or bag with desiccants. Moisture can negatively impact the quality of filament and lead to print issues.

Dust Control: Dust and debris can clog your printer’s nozzle and affect print quality. Regularly clean your printer, especially the nozzle and build platform.

Electrical Safety: Ensure your 3D printer is properly grounded and connected to a surge protector. Avoid daisy-chaining multiple devices on a single electrical outlet.

Emergency Shutdown: Be familiar with your printer’s emergency shutdown procedures in case of unexpected issues.

Knowledge is Power: Educate yourself about your specific 3D printer model and the filaments you plan to use. Understanding your equipment and materials can prevent mishaps.

Print Monitoring: While it’s tempting to leave your printer unattended, regularly check on your prints, especially during the initial layers. This allows you to spot and address issues early.

First Aid Kit: Have a basic first aid kit available in your workspace. Accidents can happen, and it’s best to be prepared.

Printer Maintenance: Regularly maintain and clean your 3D printer. Lubricate moving parts, tighten loose screws, and replace worn components as needed.

Responsible Disposal: Dispose of failed prints and support materials in an environmentally responsible manner. Some materials may not be suitable for standard recycling.

By adhering to these safety practices and maintaining a clean and organized workspace, you can minimize risks and ensure a safer 3D printing experience. In the next section, we’ll explore where to purchase high-quality 3D printing filaments and reliable sources for your printing needs.

Section 7: Conclusion

As you’ve explored the wide world of 3D printing filaments, you’ve learned vital information on how to choose, use, and care for these materials. Let’s review the main conclusions:

Variety of Filament: There is a large selection of filaments available, ranging from PLA to speciality materials such as metal and wood-infused filaments. The filament you choose should match the specifications and objectives of your project.

Filaments Particular to a Project: Every type of filament has distinct qualities and is appropriate for a variety of uses. When choosing, take into account elements like strength, flexibility, resilience to temperature changes, and aesthetic appeal.

Successful Printing: Careful consideration of the print parameters, temperature management, adherence of the bed, calibration, and cooling are necessary for successful 3D printing. The quality of your prints can be improved with routine monitoring and post-processing.

Safety and Storage: Make safety the top priority in your 3D printing workstation by making sure that there is enough ventilation, that electrical safety is maintained, and that filaments are stored in an airtight, dry environment. Strict upkeep and being equipped with first aid supplies add even more to a safe printing environment.

Constant Learning: Accept that learning is a process and don’t let bad prints deter you. Every print you an opportunity to advance your knowledge and abilities.